Are You Looking For Automation? Automation Manufacturing Operations For New and Current Systems

2019-2020 Guide To Induction and Automation – two technologies that work great together!

Inductronix’s President and CEO, Ray Ariss, joined the roster of speakers at Westec 2019, teaming up with Nic Seid from Absolute Automation to present “Automating Manufacturing Operations with Induction Technology.” If you missed the Knowledge Bar discussion, you can download a powerpoint of the presentation here.

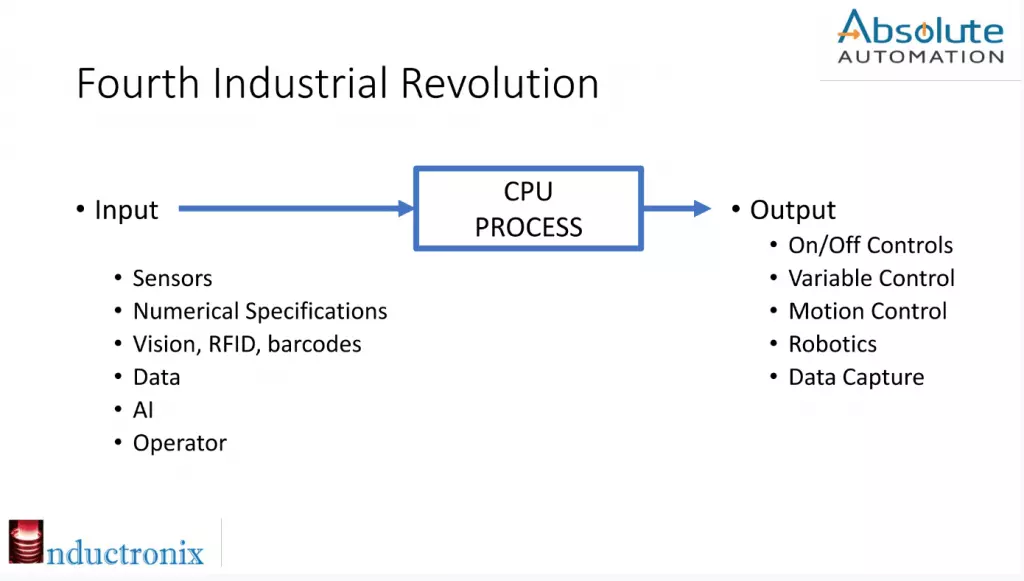

The discussion started with a description of “The Fourth Industrial Revolution”, which combines and builds on Mechanical Production, Science and Mass Production, and the Digital Revolution, adding inputs of:

- Sensors

- Numerical Specifications

- Vision, RFID and Barcodes

- Data

- Artificial Intelligence

- Human Intelligence (the operator)

plus CPU Processing Power, to produce Control Outputs including:

- On/Off Controls

- Variable Control

- Motion Control

- Robotics

- Data Capture

Fourth Industrial Revolution CPU Process

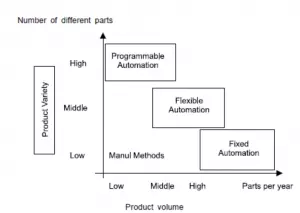

The particular type of automation that would work best for your manufacturing operation depends on different factors, particularly product volume and product variety. Classifications of automation include: Programmable, Flexible, and Fixed. Programmable Automation is most suitable to low-to-high volume/high product variety, while Fixed Automation is more suited to high volume/ low product variety.

Fixed automation, combined with your existing or new induction equipment, can provide an excellent, cost-effective solution for fastener manufactures where millions of the same type of fastener are manufactured annually. Flexible automation provides the most flexibility for industries such as medical, where there is more product variety. Finally, programmable automation is most suited for high product variety but lower volumes, for instance manufacturers who do a lot of customized work.