Induction Heating Applications

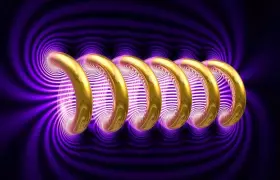

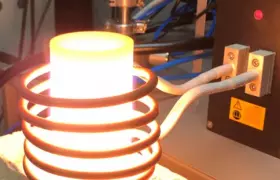

Most applications that heat metal are candidates for induction heating, from forging (yes, think iron-age sword forging) to casting to brazing to heat treating to crystal growing. In addition to direct heating, i.e., applying heat directly to a metal workpiece for brazing, there are also many applications of heat treating that use indirect heating for non-metal material. For instance, induction can heat a metal pot or pan (how induction cooktops work), a susceptor, a metal pipe, or any other metal container, indirectly heating your lunch or other metal or non-metal contents.

Fast Delivery on most products! No premium!

Our Customers:

Unsure which induction heating solution is right for your application?

Our experts are ready to help!

Ask a Heating ExpertDirect Induction Heating Applications

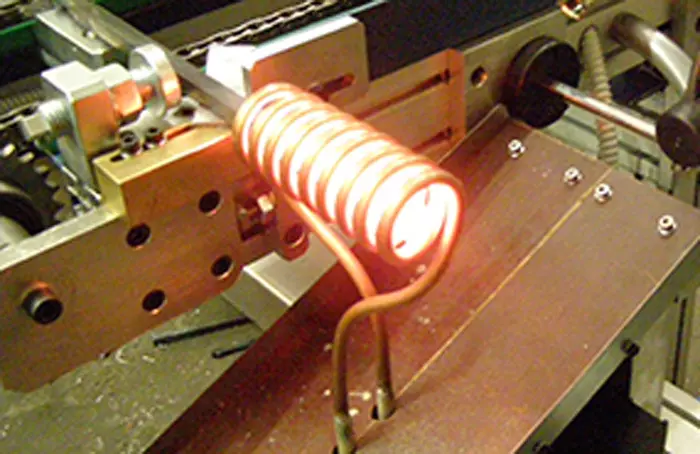

Fasteners

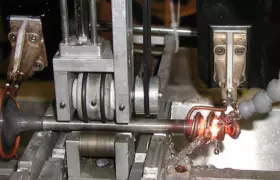

Fastener manufacturing is a great example of an application using induction. Wire made of titanium or another material is heated inductively in less than a second, then fed into a hot-header that cuts and stamps the “head” on the wire, to create the fastener (screw). As fastener manufacturers are making hundreds of thousands of parts, and are often audited for consistency in the manufacturing process, it’s vital that the entire process be documented and repeatable.

Hardening and tempering, particularly of steel, is probably one of the oldest induction heating applications. A prime example is hardening gears, sprockets, and chains for chain saws.

Hot Heading using Induction

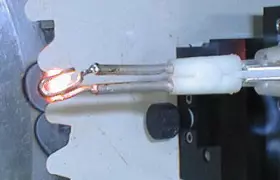

Induction Brazing

Brazing

Brazing, particularly aluminum brazing, can be quite tricky. Induction is an excellent choice for brazing as the current generation of induction generators can sense what material you’re brazing and automatically tune to provide the proper heat, time and time again.

Indirect induction heating applications

Non-metal material of all sorts can be heated with induction by pushing it through or placing it in a metal container and heating the metal container. One of our customers is pushing organic material through a metal pipe in order to char the material. Another customer is doing something similar with recyclable material in order to break it down into a more usable form.

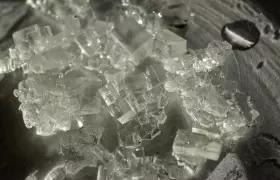

Crystal growing is a relatively new application for induction. For crystal growing, the crystal growing solution is placed in a graphite susceptor, which is heated with induction. Crystal growing is an extremely exacting science, where the smallest temperature fluctuation can ruin expensive solution. Heating the graphite to the exact required temperature is an application tailor-made for the latest generation of high-tech induction generators, which provide fine-tuning.

This is just a small sampling of the types of applications that use induction heating. Our systems are flexible enough to be used in a wide variety of induction heating applications. Thanks to the extremely high energy efficiency, guaranteed reliability in time and reduced overall size, our Induction Generators, Control Units and Optical Pyrometers are complemented by all the main automatic machine manufacturers (OEM), and have been used successfully in all those applications where the process repeatability, the constant power supply, and the accurate temperature control are essential.

Why choose induction technology solutions?

Free Application Testing & Demos Available

Large In-Stock Inventory for Fast Lead Times

Lower Cost & Increase Productivity with Automation

Personable Customer Service