Do You Need Automation? Induction Heating Automation Guide For New and Existing Systems

Adding Automation To Induction Heating

We had a great turnout at the 2019 Westec’s Manufacturing Technology Event! I was invited by the organizers to talk about Automation Manufacturing using Induction Heating, one of my favorite topics. It was supposed to be a 15-minute discussion but ended up being about 1.5 hours of production conversations with potential customers. We touched on:

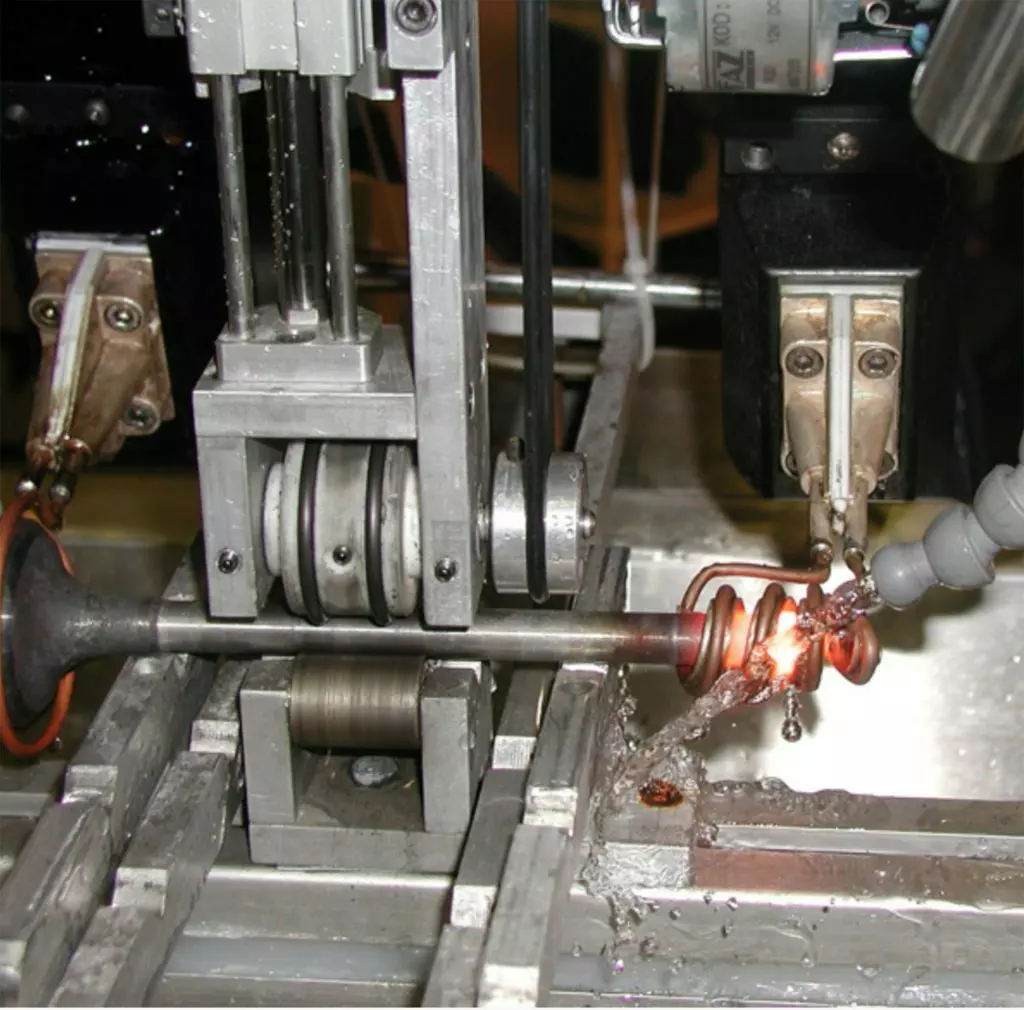

1. How to add automation to your induction heating operations, including soldering, brazing and annealing.

2. How to do your own Induction Heat Treating in-house and perhaps do away with your outside Heat Treater.

3. How to add Infra-Red temperature measurement to your new Induction Heating automation system, specifically how to: a. Heat a part and measure its temperature accurately each and every time; b. Select an IR sensor to measure the temperature of various metals being heated, even tricky ones like Aluminum, without having to keep the changing the Emissivity of the IR sensor; c. Set up an IR sensor to turn off the induction heater once the workpiece has reached its target temperature; d. Monitor, heat profile and data acquisition.