Manufacturing Automation For Induction Heating Systemsnest

How can I increase my production, be cost-effective, keep my existing employees, and still be competitive?

We get asked some variation of that question every day. So below, we introduce a 3-part solution involving manufacturing automation and automating induction heating systems.

Manufacturing Automation For Induction Heating Systems can be Quite Cost Effective

In many cases, manufacturing automation can be added to your existing production systems, no need for capital expenditure on new induction machines. A semi or fully automated system can make your employees more efficient. For instance, with the aid of automation, an operator can run multiple lines at the same time; they could begin an Automation Cycle on line 1 and then continue working on line 2. Automation can help you run more efficiently and save existing jobs while minimizing the cost of having to hire and train temps during peak production times.

Automation Systems for Manufacturing –Some Real-Life Examples

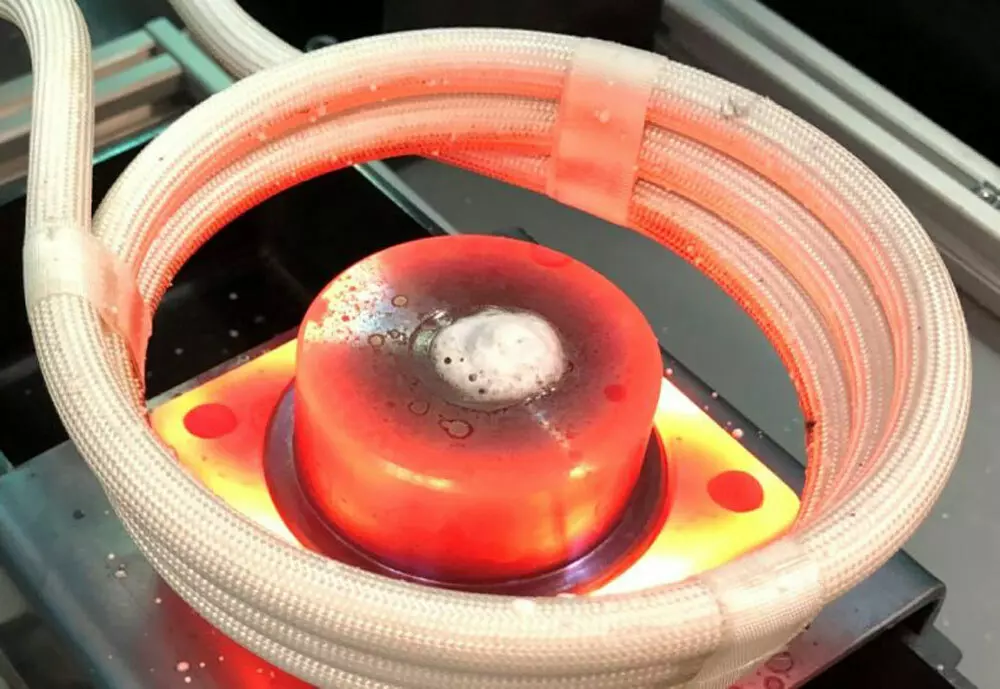

Soldering System with Automatic Solder Wire Spooling, Applying Soldering – In an Open Air or Vacuum – Argon Atmosphere:

Automated Soldering Stations

Inductively heat a workpiece to its target temperature, then apply a pre-determined amount of solder accurately, each and every time. As shown below, an operator can set up the process, press the Start-Cycle button, and then walk away and the system will automatically complete the heat-and-solder cycles.

Automated Annealing Stations.

Forging, vertical and horizontal type, feeding a billet to and from the induction heating coil.

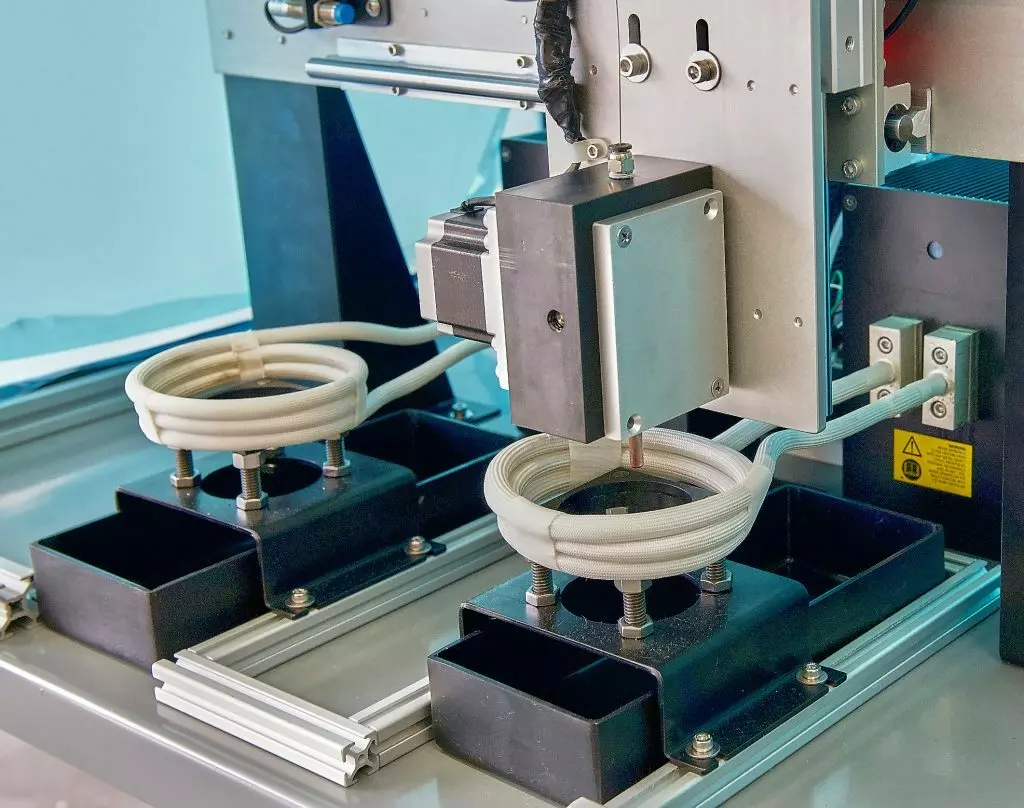

Adding Automation To Induction Heating System: This is a Dual-Induction Soldering Station By Inductronix – Induction Technology Solutions Inc.

Obsolesce & Future Expansion Concerns:

We design our automation systems so that they can always be taken to the next level; a semi-automatic can be converted to a fully automatic, depending on the application and its feasibility, of course.

For Success, Monitor, Document, Production Repeatability

Infra-Red Temperature Measurements & Data Logging:

Highly accurate Infra-Red Pyrometers can be added to measure and monitor the workpiece temperatures. All relevant production data and “recipes” can then be uploaded to most third-party database systems (e.g. Industrial Automation 2.0 systems) for analysis and storage.

Increase Production Throughput with Induction Power Supplies Featuring Dual-Output:

Induction Heating System With Multiple Output Power Options

Production Line Back-Up & Redundancy

With the Dual-Output Induction Heating System, you can have two production lines running at the same time, or use the system to improve your up-time by building in redundancy. This means that if the first production line goes down, you can easily switch to the second output and quickly resume production.

The Best Part of Serving Our Customers with Cost Effective Automation:

We love to learn about our customers’ present and future application requirement. We conceptualize, design, prototype, and manufacture all our automation systems in-house at our local West Coast Customer Technical Center. This means that you can evaluate, qualify, and run the automation system prior to the delivery! Depending on the application, we will also come on-site to install and start-up your system.