Selective Heat Treatment Using Localized Induction Heating

A California Founded, Dedicated, Passionate, and Adorable Induction Heat Treatment Team!

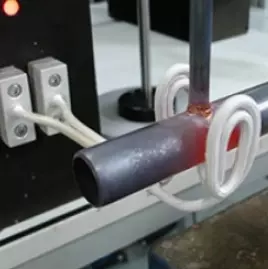

Selective Heat Treatment: Being able to heat just a portion of a workpiece, minimizing the heat traveling to the rest of the material.

Looking for selective heat treatment? Localized induction heat treatment is the best way to achieve reliable, reproduce-able results – and not just for steel! Check out the video below for localized heat treatment of titanium. The customer wanted to selectively heat just one narrow part of the workpiece, without heating the rest of the part.

A typical application might be tool brazing a carbide tip onto a tool – no affecting the hardness of the rest of the work piece. Another application might be tin soldering one area of a connector assembly, where heating the entire assembly could end up melting attached cables, burning insulation.

Coils can be as small as 0.2″ i.d. to pinpoint heat exactly and only where needed.

I have been asked to make a quick video showing “Selective Induction Heat Treatment” of a workpiece.

Material: A6AL titanium aircraft grade.

Goal: Heat a small area of the workpiece.

Does the part have to glow red? No, I just love heating the part until it does, and it really shows how the heat is concentrated in just the area of the part where the coil is positioned. It’s really fun, until the part melts and makes a mess! We won’t let it get that far in a production environment, of course. That’s the joy of induction – you can control and fine-tune the exact time and temperature to your specific requirements.