Induction Heating Coil Design

Problems with your induction applications could be due to the Induction Coils.

Induction coils are the energy transmitter for the induction power supply – radio frequency (RF) generated in the coil creates a magnetic field that then gets induced into the workpiece, heating it up.

An issue with the coil could compromise your application and your entire manufacturing process. Do any of these problems sound familiar?

- Underheated parts

- Overheated parts

- Inconsistent heating

- Shorting

- Damage to parts

- Coil overheating

- Induction heating power supply tuning issues

Scroll down to take a deeper dive into some of these problems.

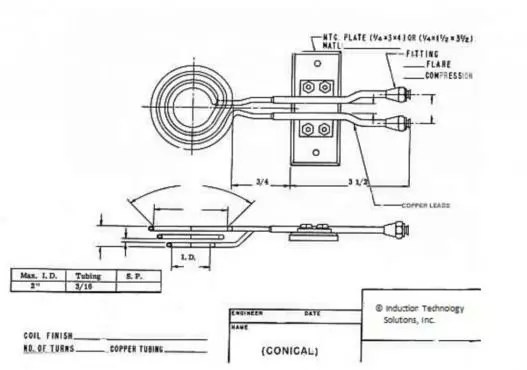

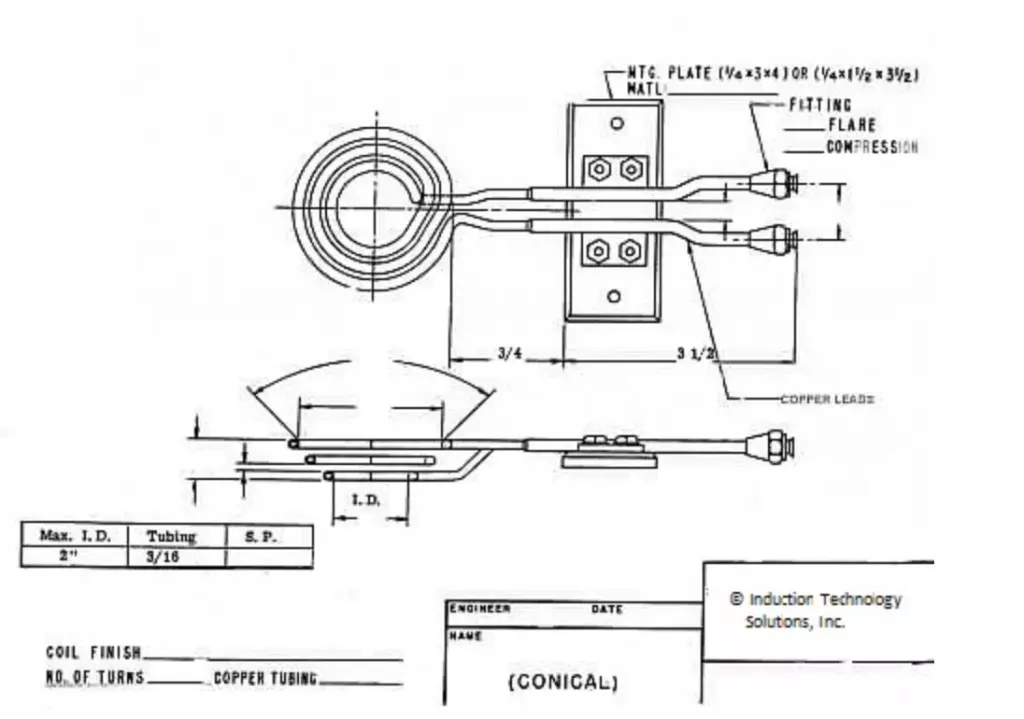

Conical Induction Coil

Overheating

Are your parts overheating or worse, melting? While induction is great because you can control the process, sometimes getting the process down exactly can be tricky, particularly if you’re using your induction heater and induction coil for multiple applications. Induction coils are not one-size-fits-all: An induction coil with five turns, for instance, might be great at heating large-diameter parts but the resulting RF field could turn a smaller diameter piece into a dripping mess.

You don’t necessarily need to buy a different induction heater for every application, though – as long as your induction heater is properly sized and tuned, you may just have to switch coils.

If you’ve been using the same coil and induction heater for your application for a while, but have suddenly started having overheating issues, you need to look at a couple of other factors:

- Has the distance of the workpiece from the coil changed? Possibly the fixture holding the workpiece in place has shifted or has been damaged.

- Does the induction heater need re-tuning? Are there power fluctuations on the panel, or any kind of machine faults noted?

At Inductronix, we know the right induction coil is vital to your induction heating application.

We can build and design custom induction heating coils to your specifications or our Applications Engineers can work with you to determine the best coil design for your application.

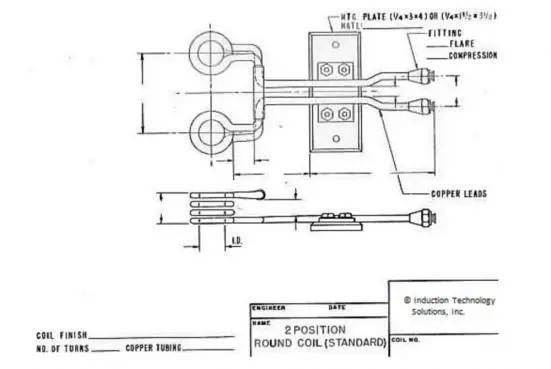

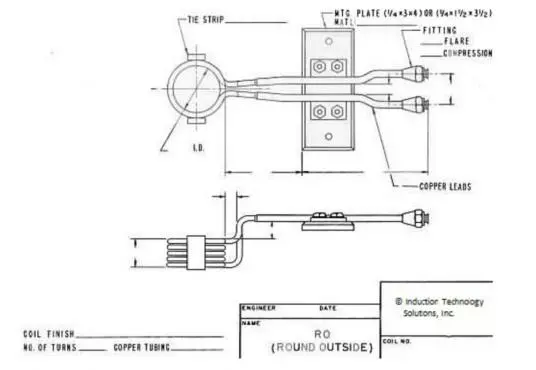

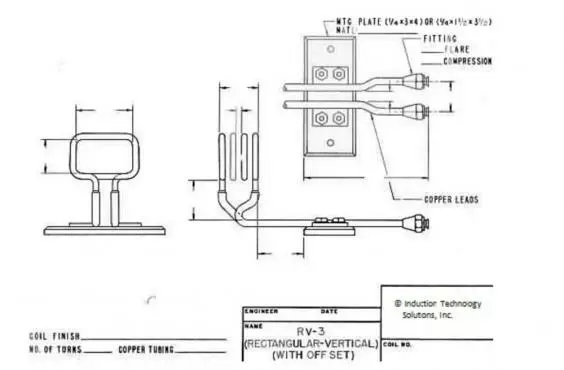

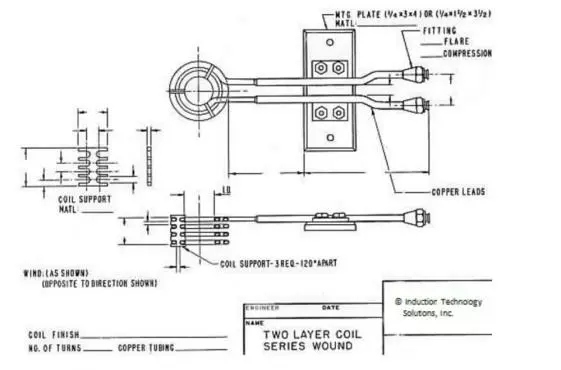

Below are just a few of our basic coil designs that can be ordered to your size and fittings.

About Us

At Inductronix, we have decades of experience in the induction field.

We can meet your induction heating coil design needs in a prototype and a production environment with U.S. made coils at a reasonable price, backed with a full year warranty against manufacturing defects.

In many cases, we can have an induction coil out to you in about one week.

Send us the details of your application and material and we will get back to you with a quick quote. Also check out our complete induction heating solutions. We look forward to hearing from you!

Try our free calculator

Check out our Induction Heating Calculator for running basic calculations to help you size your induction heating applications.

Why choose induction technology solutions?

Free Application Testing & Demos Available

Large In-Stock Inventory for Fast Lead Times

Lower Cost & Increase Productivity with Automation

Personable Customer Service