Induction Forging & Hot Forming Applications

Why induction for forging and hot forming applications? When you think of forging, do you think of Vulcan, sweating and laboring over his forge? Those days are over!

Induction Forging offers key advantages

- No open flames, no more need for using Oxy Acetylene torches or storing flammable gas tanks. Induction is clean, flameless, safe.

- Fast and energy-efficient – Quick/Instant On features make induction energy and cost efficient.

- Localized heating: Precise “useful” heat can be focused only to the area to be treated.

- Consistency & Repeatability: Evenly applied heat.

- Automation: Feeders, scanners, heating – all can be automated with cost-effectively.

- Using our optional Master Controller V3+, you can control for Power and Temperature, or Power and Net Heating Time Presets for each braze joint diameter. Use the Controller’s “Quick Access” menu to pull up all the Presets for required braze joints prior to the day’s production run.

Why Inductronix for Induction Forging and Hot Forming?

Our systems verify that the part has reached the target temperature, using dual-color optical pyrometers. The induction power supply’s settings (power, temperature) are stored in our data logger and can be recalled by work order and downloaded as a .csv or, using our proprietary software, you can see the data graphically. Verified, repeatable, logged results, every time.

Thermal Profile Management and Monitoring

- Up to 20 Programmable Temperature and Time Segments per Process

- Up to 100 different storable processes

- Maximum Power Output Programmable for Each Individual Segment

- Temperature Tolerance Window Programmable for Each Individual Segment

- Out-of Tolerance and End-of-Cycle Outputs for Each Process

Thanks to the Thermal Profile Monitoring software, coupled with the new SH15/SLE Optical Pyrometers, the user is now able to set specific temperature profiles, and monitor and certify the heating process of each production item.

Real-time Thermal Profile Screen, combined with Web server and Data Log option

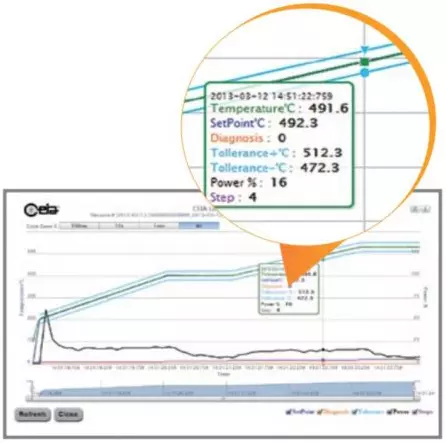

Integrated Web Server and Data Log System

- Integrated Webserver with 2-port 100base-T Ethernet switch

- No client software required, only a web browser

- Zero configuration network for simple setup

- Built-in Rich Internet Application (RIA) for Status Monitoring, Remote Programming, Logging and Thermal Profile Management

- Internal storage capacity for more than 100,000,000 data samples

Data Logger Screen

New Add-On Feature Available

In addition, we also have a new add-on feature called Thermal Profile, where you can see a temperature/power graph on-the-fly as you’re heating the wire. You can see any temperature variations in real-time.

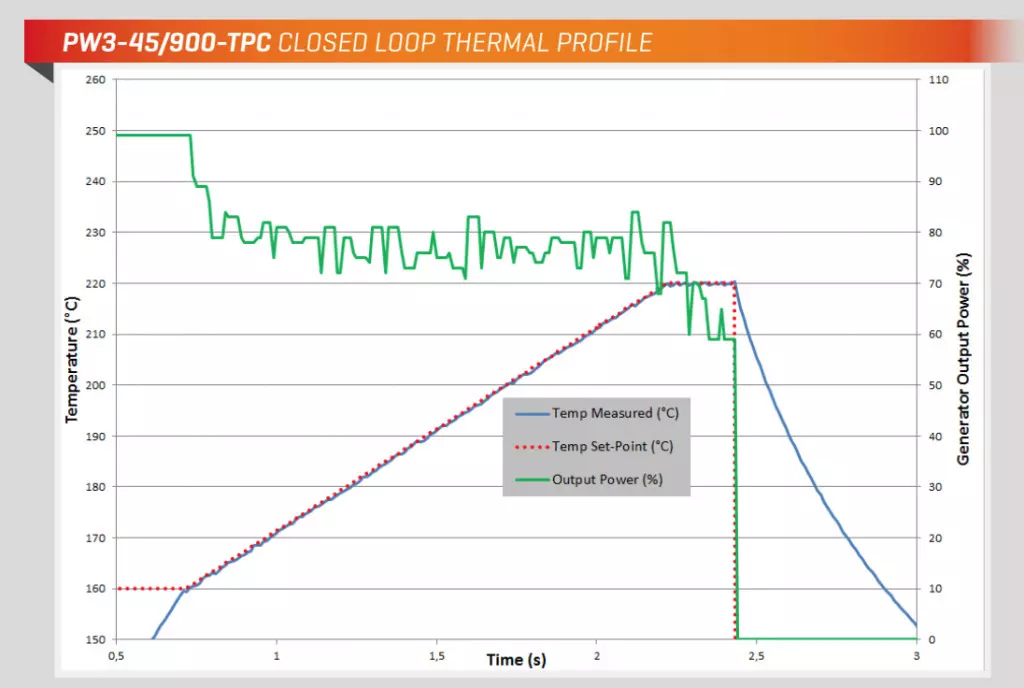

The very fast response time of the Integrated Controller (=0.5 ms) allows for very precise and sharp temperature control.

About Induction Technology Solutions Inc.

Headquartered in Anaheim California, Inductronix offers complete induction solutions for various industries throughout North America. We have a combined 120 years of experience in various types of application requirements.

We offer a variety of Induction Heating Power Supplies and systems of all Output Power and Frequency ranges, Cooling Systems, Induction Heating coils, and now automation, to accommodate your specific heating requirement. We also can provide engineering support, such as evaluating a sample of your product that needs to be heated to help you determine the best and most cost-effective solution for your production requirement.

Try our free calculator

Check out our Induction Heating Calculator for running basic calculations to help you size your induction heating applications.

Why choose induction technology solutions?

Free Application Testing & Demos Available

Large In-Stock Inventory for Fast Lead Times

Lower Cost & Increase Productivity with Automation

Personable Customer Service