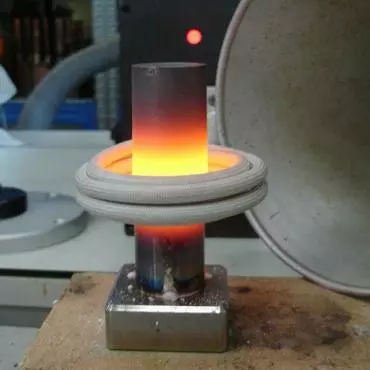

Induction Brazing Equipment & Applications

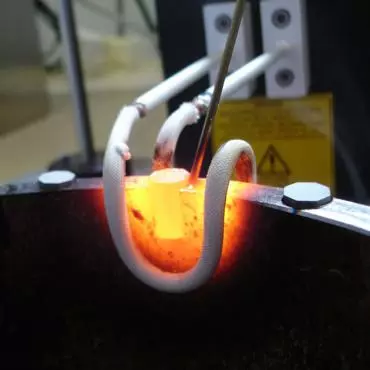

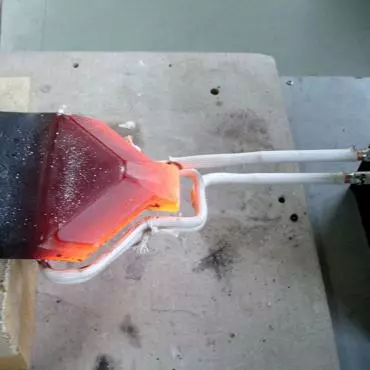

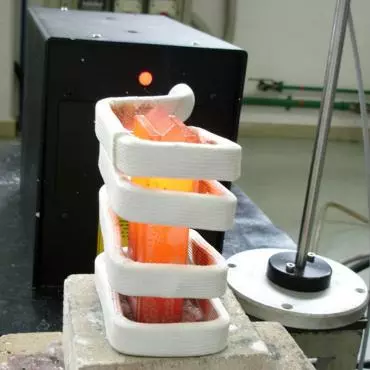

High-Temperature Brazing

Our induction heaters are particularly suited for high-temperature brazing and soldering applications for steel, copper, inox steel, aluminum, and other metallic alloys.

What is Induction Brazing?

Induction brazing is a process that uses electromagnetic induction to heat metal components to a temperature above the melting point of a filler metal (braze alloy) but below the melting point of the base metals being joined. The molten filler metal is then drawn into the joint by capillary action, forming a strong bond between the components.

Metals that can be Induction Brazed?

- Steel

- Stainless Steel

- Copper

- Brass

- Aluminum

- Nickel & Titanium Alloys

- Bronze Alloys

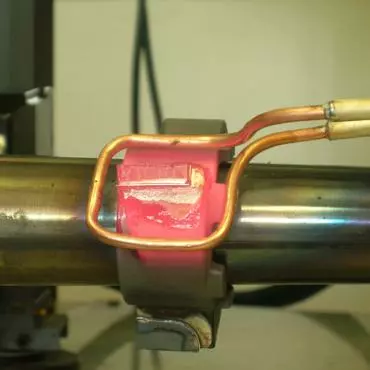

Induction Brazing Offers Key Advantages Over Flame Torch Brazing

- No open flames, no more need for using Oxy Acetylene torches or storing flammable gas tanks. Induction is clean, flameless, safe.

- Localized heating: Precise “useful” heat can be focused only on the required joints to be brazed.

- Consistency & Repeatability: All brazed joints have heat applied evenly, and the brazed results are repeatable.

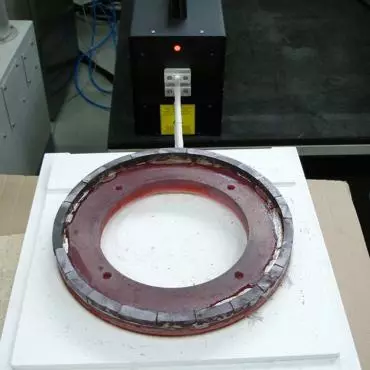

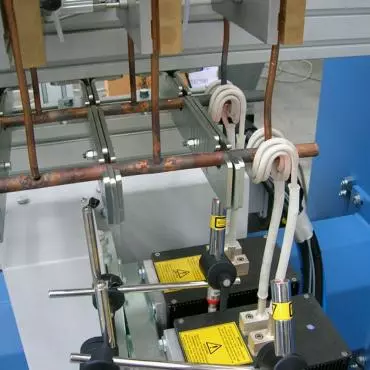

- Automation: Feeders, scanners, heating – all can be automated with cost-effectiveness.

- Quick/Instant On features make induction energy and cost-efficient.

- Can be done in an atmosphere for a nice clean braze – no post-cleaning required.

- Using our optional Master Controller V3+, you can control for Power and Temperature, or Power and Net Heating Time Presets for each braze joint diameter. Use the Controller’s “Quick Access” menu to pull up all the Presets for required braze joints prior to the day’s production run.

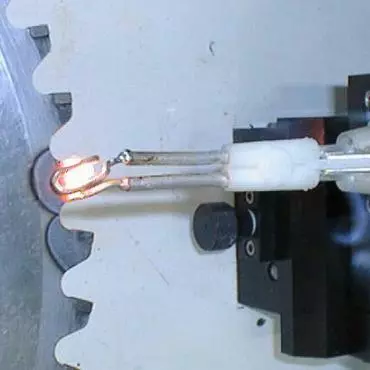

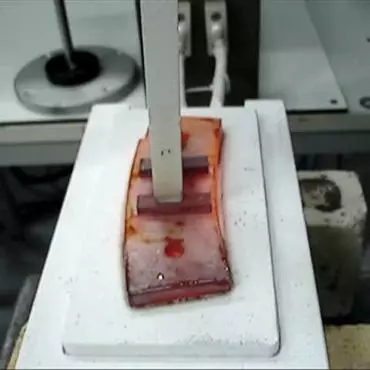

Brazing for Localized Brazing or Debrazing of Tools

Our induction heating equipment for brazing applications offer extremely accurate temperature control, allowing the heat to be localized at the soldering area only, and safeguarding the metallurgical properties of the hard metal and cutting tip.

The alloy distribution can be applied using wire feeders having diameters from 0.3 to 1.5 mm. The quantity, speed, feed force, and times of wire distribution are completely programmable.

The very small footprint of our induction heaters and of the heating heads allow for their placement in even very tight working environments, and the high conversion efficiency (greater than 95%) contributes to reducing operating costs.

Learn More About the Induction Heaters Pictured Above

Try our free calculator

Check out our Induction Heating Calculator for running basic calculations to help you size your induction heating applications.

Why choose induction technology solutions?

Free Application Testing & Demos Available

Large In-Stock Inventory for Fast Lead Times

Lower Cost & Increase Productivity with Automation

Personable Customer Service