Medical & Dental Industry Induction Heating

Induction heating applications for the medical and dental industry include:

- Catheter Tipping

- Crystal Growing for Lasers

- Soldering small contacts for medical devices and equipment

- Tube forming

- Induction Soldering for Electronics in Medical Devices

- Induction Brazing

- Annealing of Medical Wires

- Sterilization of Medical Instruments

- Hardening of Surgical Instruments

Induction offers key advantages

- No open flames, no more need for using Oxy-Acetylene torches or storing flammable gas tanks. Induction is clean, flameless, safe.

- Fast and energy-efficient – Quick/Instant On features make induction energy and cost-efficient.

- Localized heating: Precise “useful” heat can be focused only to the area to be treated.

- Consistency & Repeatability: Evenly applied heat.

- Automation: Feeders, scanners, heating – all can be automated with cost-effectively.

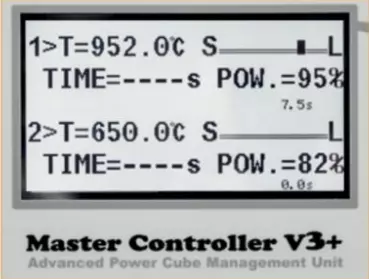

- Using our optional Master Controller V3+, you can control for Power and Temperature, or Power and Net Heating Time Presets for each braze joint diameter. Use the Controller’s “Quick Access” menu to pull up all the Presets for required braze joints prior to the day’s production run.

high-definition graphic display

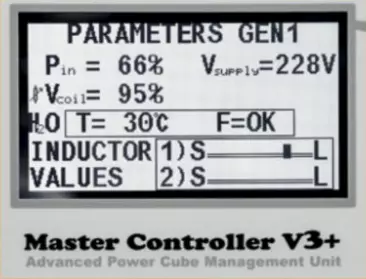

The main programming parameters of the two heating stations are shown on the display of the CEIA Master Controller. A bar-graph Indicator shows the correct matching of the inductor. Changes in operating conditions, such as load variations, are displayed in real time.

A service menu, accessed by pressing the STATUS key, displays a summary of the internal generator operating parameters.

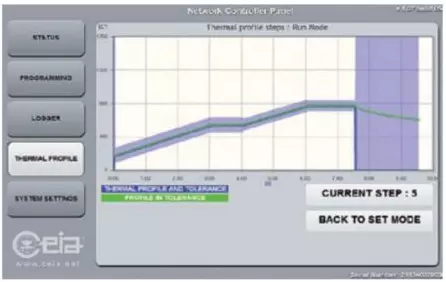

Thermal Profile Management and Monitoring

- Up to 20 Programmable Temperature and Time Segments per Process

- Up to 100 different storable processes

- Maximum Power Output Programmable for Each Individual Segment

- Temperature Tolerance Window Programmable for Each Individual Segment

- Out-of Tolerance and End-of-Cycle Outputs for Each Process

Thanks to the Thermal Profile Monitoring software, coupled with the new SH15/SLE Optical Pyrometers, the user is now able to set specific temperature profiles, and monitor and certify the heating process of each production item.

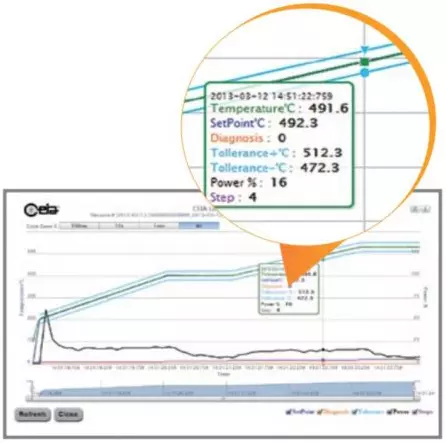

Real-time Thermal Profile Screen, combined with Web server and Data Log option

Integrated Web Server and Data Log System

- Integrated Webserver with 2-port 100base-T Ethernet switch

- No client software is required, only a web browser

- Zero configuration network for simple setup

- Built-in Rich Internet Application (RIA) for Status Monitoring, Remote Programming, Logging and Thermal Profile Management

- Internal storage capacity for more than 100,000,000 data samples

Data Logger Screen

Case Study for Induction in the Medical Industry – Crystal Growing

One of our customers using induction to grow crystals is working on a proprietary crystal growing process. They are using our SA/80 induction heater to heat their Graphite susceptor inductively, which in turn heats the crystal growing solution conductively, without reacting with it.

Our SA/80 series Induction Heater. This induction power supply provides:

- Highly stable output – the output power to the load is always consistent, accurate, and highly regulated.

- Calibration – our machines and our optical pyrometers are fully factory calibrated. You always know that the output power meters are accurate. Certificates available.

- Data logging for recording all heating events. view your actual temp and power graphically on-the-fly as well as recording all of your power, time, and temp. Your “secret sauce” can be all recorded and reviewed at any time.

- A built-in timer for truly consistent and replicable results.

- Low frequency for deeper heat penetration.

- Control and monitoring of all our power supply settings using their own computer, in real-time, even remotely.

- Automatic tracking and optimization.

- User Friendly Operations through graphical touch-screen interface.

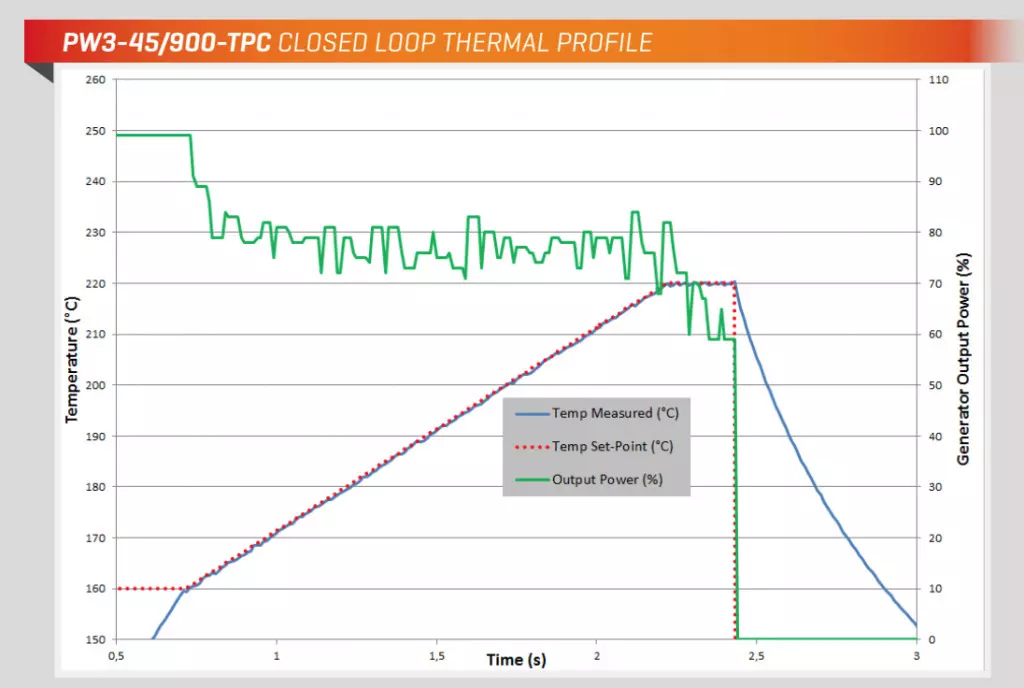

The very fast response time of the Integrated Controller (=0.5 ms) allows for very precise and sharp temperature control.

Why Induction Technology Solutions?

- Extensive Application Experience

- ISO 9001 certified

- 50 years in business

- Support – we want to partner with you and fully understand your requirement, not just

sell you a machine - Dual remote heating heads

- Dynamic auto-tuning

- Highly Accurate Temperature Measurement & Control

- Automation – all our induction heating systems are pre-wired to be automation-ready

Additional Benefits

- You can add an ethernet-enabled data logging card that keeps records all of your induction settings on-they-fly – you can see the graph being plotted real-time, as well as keeping history of all of your induction heating settings, so that you can always go back to your log and replicate your results.

- You can communicate with our induction machine – you can manage and control your induction heating process from a remote location, via Field and Bus protocol:

- Profinet

- EtherCAT

- EtherNet/IP

- Others upon request (DeviceNet, CC-Link, CompoNet, Modbus-RTU, and others)

- Field Bus and Network Compliance Certification

- You can control and monitor all our power supply settings using your own computer, in real-time, even remotely at a different location.

Try our free calculator

Check out our Induction Heating Calculator for running basic calculations to help you size your induction heating applications.

Why choose induction technology solutions?

Free Application Testing & Demos Available

Large In-Stock Inventory for Fast Lead Times

Lower Cost & Increase Productivity with Automation

Personable Customer Service