Induction Curing Equipment & Applications

Induction heating for curing applications involves using heat as the catalyst to initiate chemical and molecular level structural changes in polymeric materials such as epoxies, phenolics, polyesters, and silicones. These materials are then applied for bonding, protective coating, sealing, insulation, and other uses.

Advantages

The main advantages of our induction curing equipment and process are:

- Reliably repeatable performance

- Constant and consistent power output

- Localizing of the heat treatment area

- Accurate temperature control, which helps to speed up production, save energy and facilitate the quality control of the finished product.

Our induction heaters are extremely flexible and compact, suitable for being integrated both outside and inside of the machine. The high reliability of the output power allows for continuous use without damaging and costly down time. The constant power delivery provides stable and repeatable performance over time.

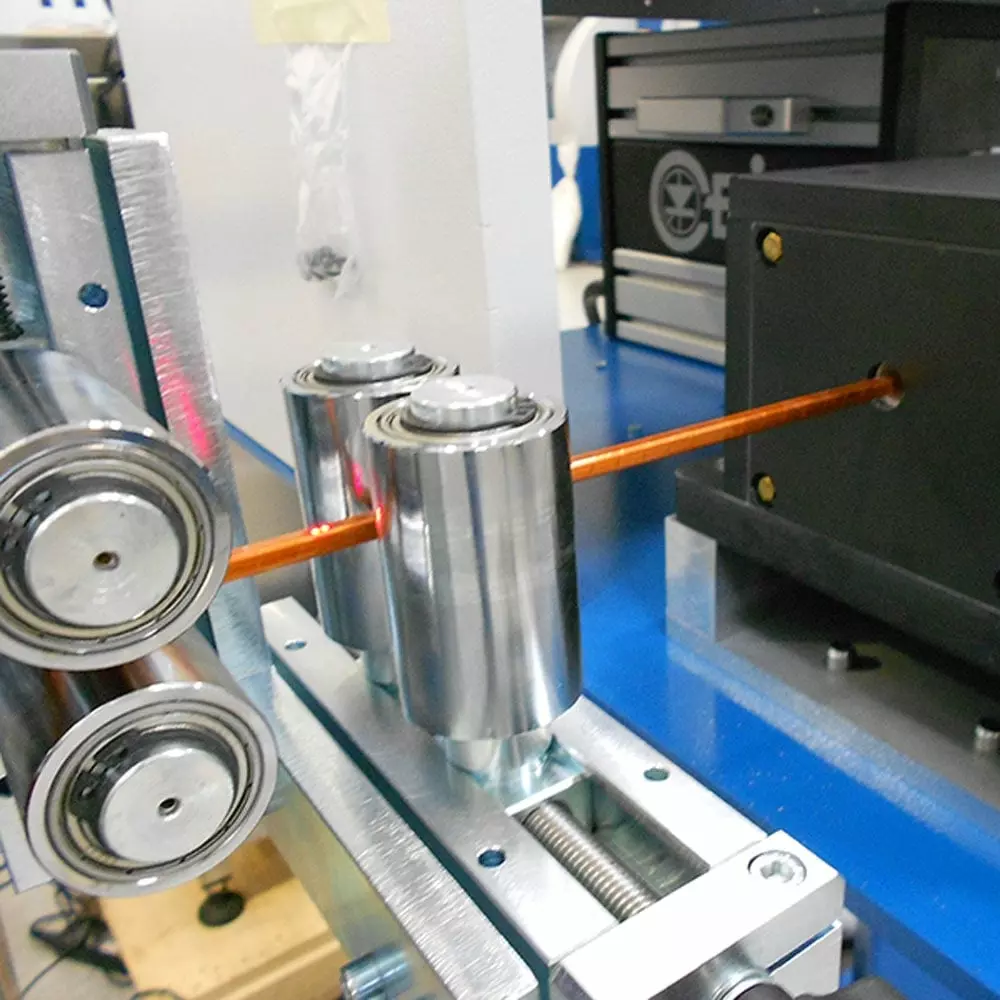

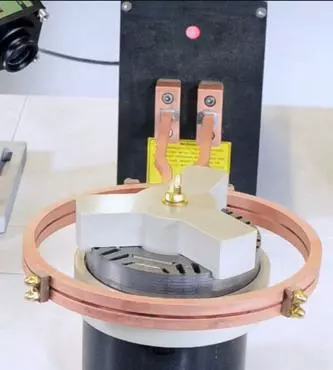

The main applications for induction curing solutions are in the automotive industry and for the production of electrical power cables.

Try our free calculator

Check out our Induction Heating Calculator for running basic calculations to help you size your induction heating applications.

Why choose induction technology solutions?

Free Application Testing & Demos Available

Large In-Stock Inventory for Fast Lead Times

Lower Cost & Increase Productivity with Automation

Personable Customer Service