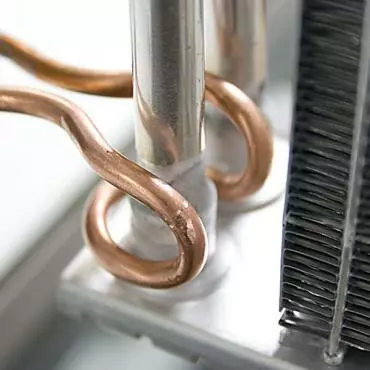

Aluminum Induction Brazing Equipment

The key advantages of using induction heating over flame torches:

- No open flames, no more need for using Oxy Acetylene Torches. Induction provides clean flameless brazing.

- No more smoke and fumes coming out of torches.

- No need to store hazardous and flammable Oxy Acetylene cylinders.

- Localized heating: Precise “useful” heat can be focused only to the required joints to be brazed.

- Consistency & Repeatability: All inductively brazed joints have applied even heat, and the brazed results are repeatable and logged using the data acquisition module.

- Automation: You can add an affordable automation to an induction heating system.

- Data-Logging: Using our optional Master Controller V3+, you can program Power and Temperature or Power and Net Heating Time Presets for each braze joint diameter; use the Controller’s “Quick Access” menu to pull up all the Presets for a required braze joints prior to a day’s production run.

Return On Investment For Replacing Flame Torches With Induction Heating

- Using an Induction Heating, there are no consumables. The induction heating coils when treated well and water-cooled and do not degrade over time. Buying these coils is almost a one-time investment; additional coils might be needed for spare and or for new brazing application requirements and that’s it.

- Our affordable, compact, and energy-efficient aluminum induction brazing equipment is a one-time investment; its highly reliable and dependable design enables the generators to operate for many years to come.

- The Induction Generators can power up immediately, no warm-up is required. This means that you can leave the generator in stand-by mode without drawing any significant amount of Current from

your factory Input Voltage Supply. - An efficient cooling system provided will last for many years as well. You just fill the embedded water tank with distilled water and just check the levels quarterly.

Please contact our factory for free Return On Investment Calculations.

Induction Heating for Aluminum brazing is particularly tricky as the melting temperature of the brazing alloy is very close to the melting temperature of aluminum itself. Aluminum’s brazing temperature range is 550 degrees C to 650 degrees C (1022 degrees F to 1202 degrees F).

Can All Aluminum Alloys Be Brazed?

Not all Aluminum alloys can be brazed. Some of these alloys have a lower melting temperature than the commercially available brazing filler materials, and so one has to consider the type of Aluminum that can be used for brazing. This type of research can be done by contacting companies such as Lucas Milhaupt, where they provide all types of brazing filler materials that might be applicable for your type of Aluminum alloy type and Brazing requirement.

Our induction heaters are perfect for aluminum brazing because of the efficient, stable, and regulated power output, which allows for very precise temperature management. You can use our accurate Optical Pyrometer as a non-contact temperature measurement during the brazing operation.

The main Induction Heating Controller monitors the entire heat cycle dynamically and displays any possible failures that occurred during the heating of the part, entirely eliminating any guesswork.

Data Logging: How about being able to record the production run and monitor its process in your office via a server? The Master V3+ is equipped with integrated Data Log and Web Server system. It is possible to perform automatic data storage, for proper process quality control, monitoring heating temperatures, Output Power, Frequency, Voltage and Inductor Current.

If you are using Kepware then we can send all the datalogging information directly to your Server.

An Ethernet TCP/IP port allows access to the internal web server of the Master Controller for remote programming settings and interface with SCADA / DCS systems.

Try our free calculator

Check out our Induction Heating Calculator for running basic calculations to help you size your induction heating applications.

Why choose induction technology solutions?

Free Application Testing & Demos Available

Large In-Stock Inventory for Fast Lead Times

Lower Cost & Increase Productivity with Automation

Personable Customer Service