What Is Induction Heating And How Does it Work?

How Does Induction Heating Work?

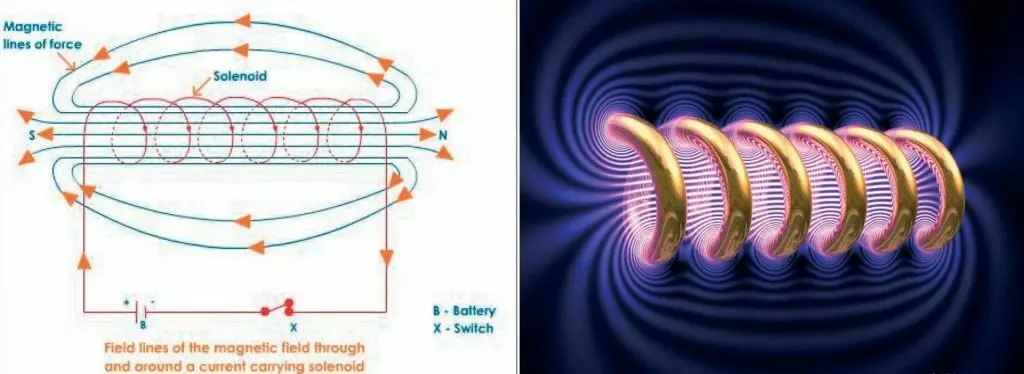

Induction Heating is a process where a metal object, magnetic or non-magnetic, is placed in a varying magnetic field, technically known as Eddy Currents. So, imagine you had a round copper coil and then you pass an alternating current through this coil, you would then generate a magnetic field within the coil.

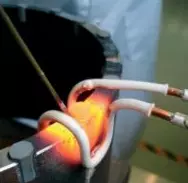

Then, if you interrupt this field by inserting a piece of metal, we called a solenoid in the photo below, inside of this coil, the magnetic field begins to wrap itself around the workpiece at a very high rate. How high a rate depends on the frequency of the applied RF field. So, for instance, if the RF frequency is 50kHz then the field will wrap itself around the workpiece 50 times per second.

As the field continues to “spin” around the metal, it begins to generate heat within the workpiece. How? Because every metal has a curtain amount of resistance within it, and this resistance effect causes the applied field to create friction within the metal, which in turn generates heat on the surface of the metal, commonly known as a Skin Effect. Depending on how long you leave the field, the heat will begin to travel through the metal by conduction.

Induction Heating Calculations

So, is there a quick and a basic way of calculating and sizing up an Induction Heating Generator for your application? The very short answer is yes you can. You are welcome to use our Fee Induction Heating Calculations tool to at least get some rough idea of what output Power is needed to heat your part.

Again, the Calculations Tool would only give you a very rough estimate of what Generator output is needed. For more in-depth calculations such as, Output Power, Frequency and Net Heating Times, you can always contact us at any time.

Helpful Induction Heating Quick Guide Links

The short answer is yes, absolutely! Some metals are a bit tricky to heat, more on in Aluminum Brazing. Does the metal have to be magnetic? Not necessarily. The metal can be magnetic or non-magnetic. Generally speaking, magnetic materials are much easier to heat with induction because the North and South poles are aligned and so the magnetic field can travel easier through these paths. But if we heat the metal above a certain temperature, then the metal may lose its magnetic property, known as a Curie Point, and it gets tough to heat after that point. More on that later.

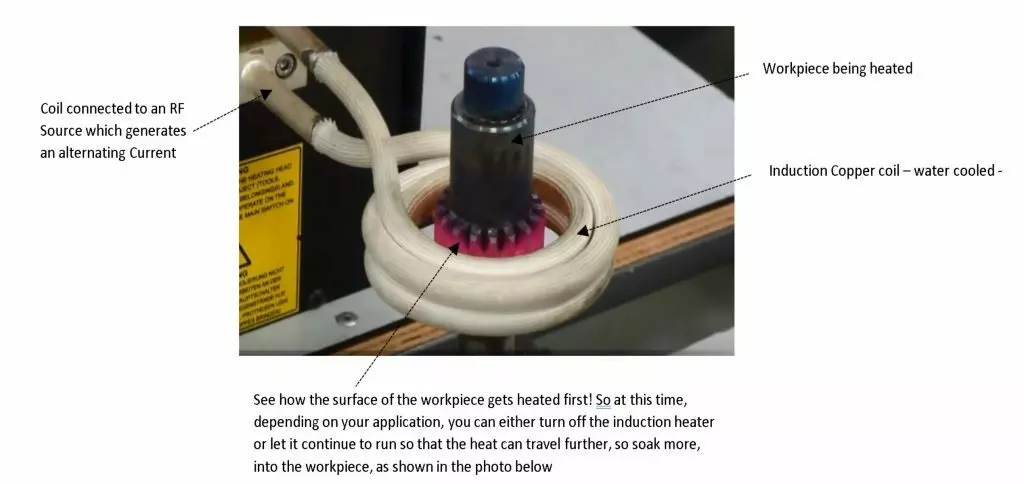

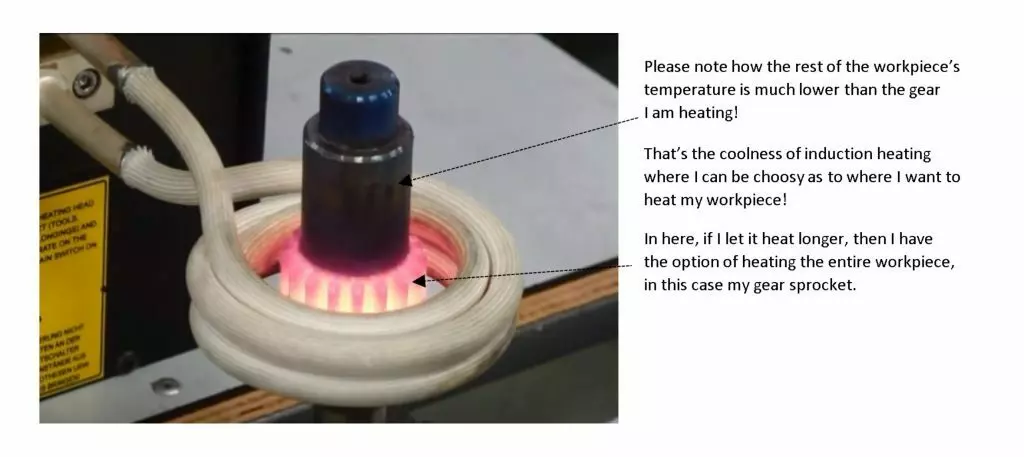

I have two photos for you to look at below, the first photo shows how the surface of a gear sprocket gets heated by induction heating, and the second photo shows how the sprocket gets heated evenly all the way through!

Selective – Induction Heating By Induction Technology Solutions Inc. West Coast Induction Power Supply Systems Company

So how come my induction coil doesn’t melt? Because I’ve run water through it. Why is a Copper coil is used? Because Copper has the least amount of resistance and it is the best conductor next to Gold.

Induction Through Heating Of A Gear Sprocket. By Inductronix – West Coast Induction Heating Company.

So, we get the surface heated by induction (Eddy Currents), and then the rest of the metal gets heated by conduction, and the cycle continues.

Yes! That’s the beauty of it!!! In most cases you can select which area of the part you wish to heat.

Yes! You can possibly heat the entire length, either by having a long induction coil, or by possibly scanning, i.e. feeding the part through the coil.

So, the induction coil never touches the part, and yet the part gets heated in a non-contact way! Since in this case the induction coil is round, the heat generated in the workpiece is always even and the heat results are always consistent; you get repeatable results workpiece after workpiece!

Induction Heating Coils

The following are the examples of various Induction Heating Coils we have built for various Induction Heating Applications. The photos are the curtesy of CEIA USA:

Benefits Of Using Induction Heating For My Application Needs?

- Non Contact, Clean Way Of Heating A Workpiece, No Flames, No Fumes, No Storage Of Highly Flammable oxyacetylene torches!

- Production Data Logging: All Of Your Induction Heating Results, Power Versus Time Or Temperature Can Be Logged And Monitored. This Means That You Can Record Your Own Power-Time Or Temperature Recipes – Your Own Factory Secret Sauce – On An Secure

Digital Card. - Quality Control Data Quick Access: You Can Quickly Access Your Pre-Qualified Production Recipes For Each Of Your Part Diameter Requirements.

- Fast & Quick Instant On, Power Available At Any Time. The Induction Machine Can Be Turned On Only When Needed.

- Consistent, Repeatable, And Always The Same Amount Of Heat Can Be Applied At Any Time.

- No Parts To Wear Out. The Induction Coil Is Always Water-Cooled, And So The Coil & The Induction Power Supply Will Last For Many Years!

- The Output Power Is Highly Regulated, This Means That The Heat Applied To A Workpiece Is Always Consistent.

- Fast & Quick Operator Training.

- In Many Cases, The Induction Power Supply System Is Portable, It Can Be Placed On A Cart To Move From One Cell To The Other.

Our Induction Heating Recipes and Our Production Secret Sauce!

- Once You Come Up With A Production Heating Times & Temperature Requirements, You Can Save & Quickly Recall These Settings.

- All Of Your Own Secret Sauce Can Be Stored So That You Can Always Recall Your Power Settings From A Job That You Ran, Say Months Ago!

Induction Heating Applications:

Just a few to mention:

- Induction Brazing, you can possibly replace flame torches with clean, selective and non contact way to brazing joints.

- Induction Soldering: You can solder RF Contacts, Potentiometer Wiper Contacts, Pre-Tinning Of Wires, We Can Always Run Application Feasibility Tests For you.

- Induction Bonding & Curing: You can use induction heating for bonding applications, curing adhesives.

Induction Heating Applications Review:

You are always welcome to contact us for any of your induction heating application requirements.